How can you improve the safety and efficiency of your heavy lifting and positioning processes?

Author

Autem Vacuum Lifters

5 minute read

In this latest informative article, member company and UK leaders in bespoke vacuum lifting technology Autem Vacuum Lifters Limited explain how vacuum lifting devices can improve the safety and efficiency for your heavy lifting and positioning processes across all industry sectors.

Technical Capabilities

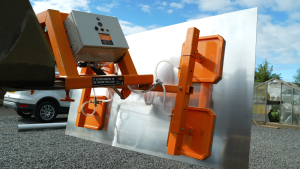

Vacuum lifting devices are specialised tools that help make heavy lifting and positioning processes safer and more efficient. They are commonly used in the manufacturing, construction, and logistics industries to move and position heavy loads usually via a gantry crane, fork-lift, HIAB, telehandler, or excavator. They use vacuum suction technology to create a secure grip on the load which allows it to be lifted and moved without the need for manual lifting and manipulation. The suction/contact pad can be made of various materials, including rubber, foam, or silicon, depending on the load material or application. The vacuum system creates a suction force that holds the load securely in place and the lifting pad is designed to distribute the weight of the load evenly to prevent damage to the load. Vacuum lifters are available in different sizes and capacities, specific to a process, application, and load material. They can lift loads from a few kilograms to more than 50 tons, from delicate components, such as glass and solar panels, through to heavy steel plate in shipbuilding, or large precast concrete structures in construction. They can be used for stacking and unstacking products, loading, and unloading trucks and ships, transferring materials between production lines, and accurately lifting and positioning materials in precision manufacturing.

Safer Lifting

One of the most significant advantages of vacuum lifters is that they can significantly reduce the risk of injury associated with lifting and manipulation of heavy or awkward loads, such as when attaching chains and slings, all of which can result in a range of injuries, including back pain, strains, and even more severe injuries such as hernias or crush injuries. Additionally, vacuum lifters allow workers to maintain a safe distance from the load during the lifting process, reducing the risk of injury from falling objects or other hazards. They also minimise the need for workers to climb ladders or scaffolding to position or move loads, which reduces the risk of falls and other accidents. Vacuum lifters also protect the load from unnecessary chain and sling rub and damage.

Efficient Positioning

Vacuum lifters can also make heavy lifting and positioning processes more efficient. Traditional methods often require a team of workers or heavy equipment to move and position loads. In contrast, vacuum lifters often only require a single operator, which saves time and labour costs; a big advantage given the labour shortages across the UK. Also, with tilt/turn/rotation options available, operators can position loads more quickly with precision and accuracy, without the additional time required to attach chains, slings, or temporary lifting eyelets. This increased efficiency can improve overall productivity and reduce project timelines, resulting in significant cost savings.

Versatility

Vacuum lifting devices are highly versatile and can be used to lift a wide range of non-porous loads, including construction materials such as wood; precast concrete pipes, blocks, and slabs; cladding and roofing panels; metal or plastic pipes and sheet; steel beams; and even more delicate items such as glass and solar panels. The devices can also be used in a range of environments, including indoor, outdoor, and offshore settings, making them an ideal tool for a range of industries. Their versatility can also reduce the need for specialised and labour-intensive temporary positioning equipment in precision manufacturing settings such as shipbuilding, further reducing costs and improving efficiency.

Environmental Benefits

Vacuum lifting devices can offer environmental benefits such as reduced emissions and lower noise pollution. They are usually powered by rechargeable battery or mains electricity, but can also be integrated and powered by the hydraulic system or electrical power of the associated excavator, telehandler, crane, etc. As the suction pump operates very quietly, they do not add to the existing plant and machinery noise levels.

Conclusion

In conclusion, vacuum lifting devices play a significant role in making heavy lifting and positioning processes safer and more time/cost efficient. They offer a range of benefits, including reducing the risk of injury, increasing efficiency and productivity, and improving environmental sustainability. As such, vacuum lifting devices are a valuable tool for a range of industries, including manufacturing, construction, and logistics, and are likely to continue to play an important role in these industries in the future.

With the Autem team’s track record of designing and manufacturing bespoke vacuum lifters over the last 20 years for a variety of manufacturing, construction, shipbuilding, aerospace, logistics, and infrastructure projects across the world, we are confident we can provide a vacuum lifting solution to meet your needs.

For further information contact Keera Dolan, Bruce Cameron or David Speirs – 01563 601 412 – sales@autemvacuumlifters.co.uk